rough-in work has wrapped up on skidmore passivhaus and it's time to look at a few of the features under the hood. this new airtight home (or shall we say leak-free) is equipped with mechanical lungs.

we chose the PH certified zehnder comfoair 200 hrv, capable of producing up to 125 cfm of continuous ventilation. this project requires about 70 cfm (60% setting) to achieve .31 air changes per hour (or roughly 1 air change every 3 hours).

the 3" flexible ductwork is a double-walled proprietary system called comfotube made by zehnder. very easy and fast to install. the goal is to keep the runs as short and straight as possible.

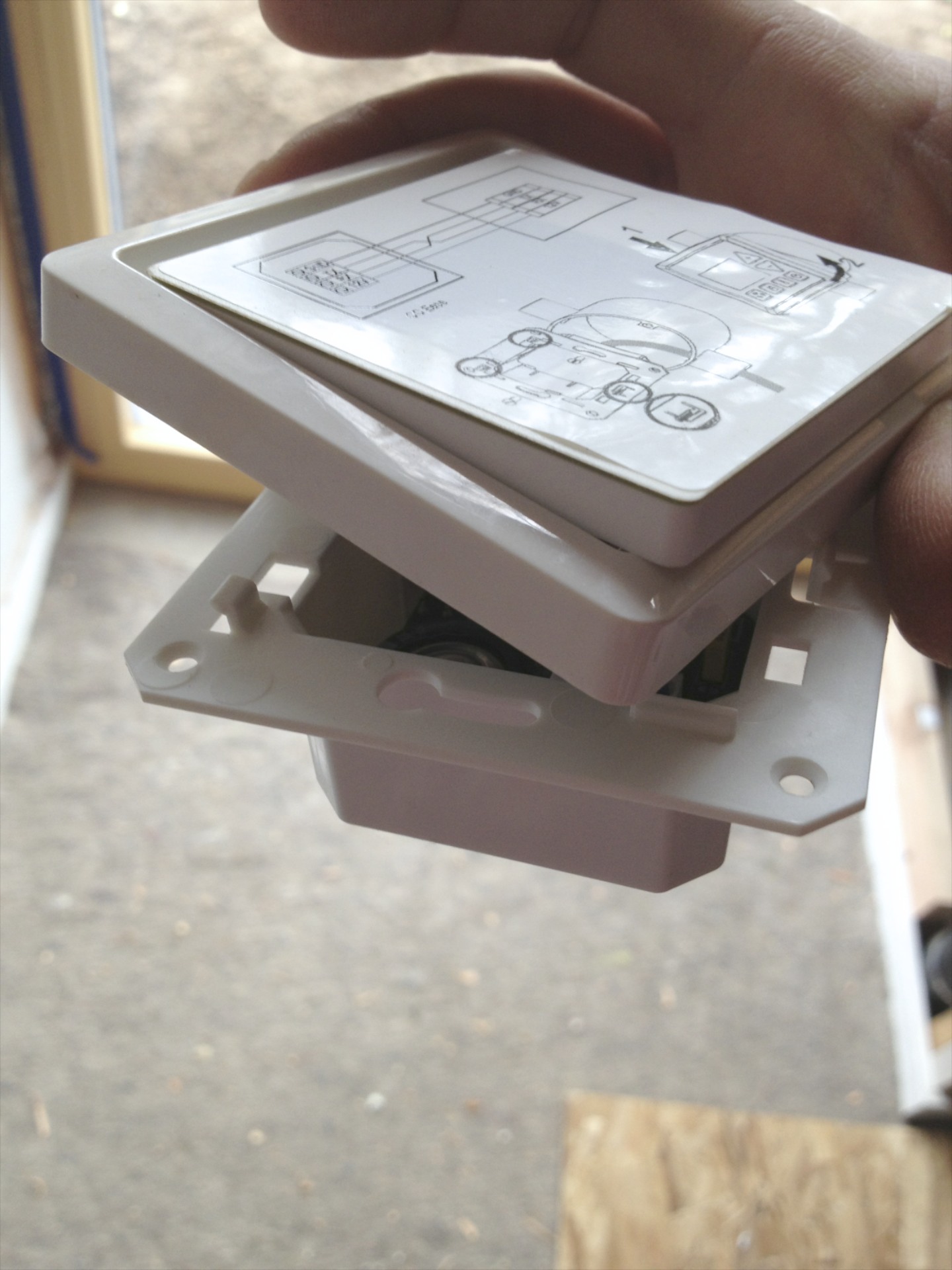

the round ceiling rough-in boxes are used for either supply or exhaust air. either 1 tube or 2 tubes are connected depending on the cfm requirements. exhausts are located in the bathrooms (20 cfm continuous) and kitchen (30 cfm continuous). we have 3 exhaust locations - each with 2 tubes. there are 4 supply locations.

supply air is typically provided at the ceilings but we have a low supply register in the double height living room.

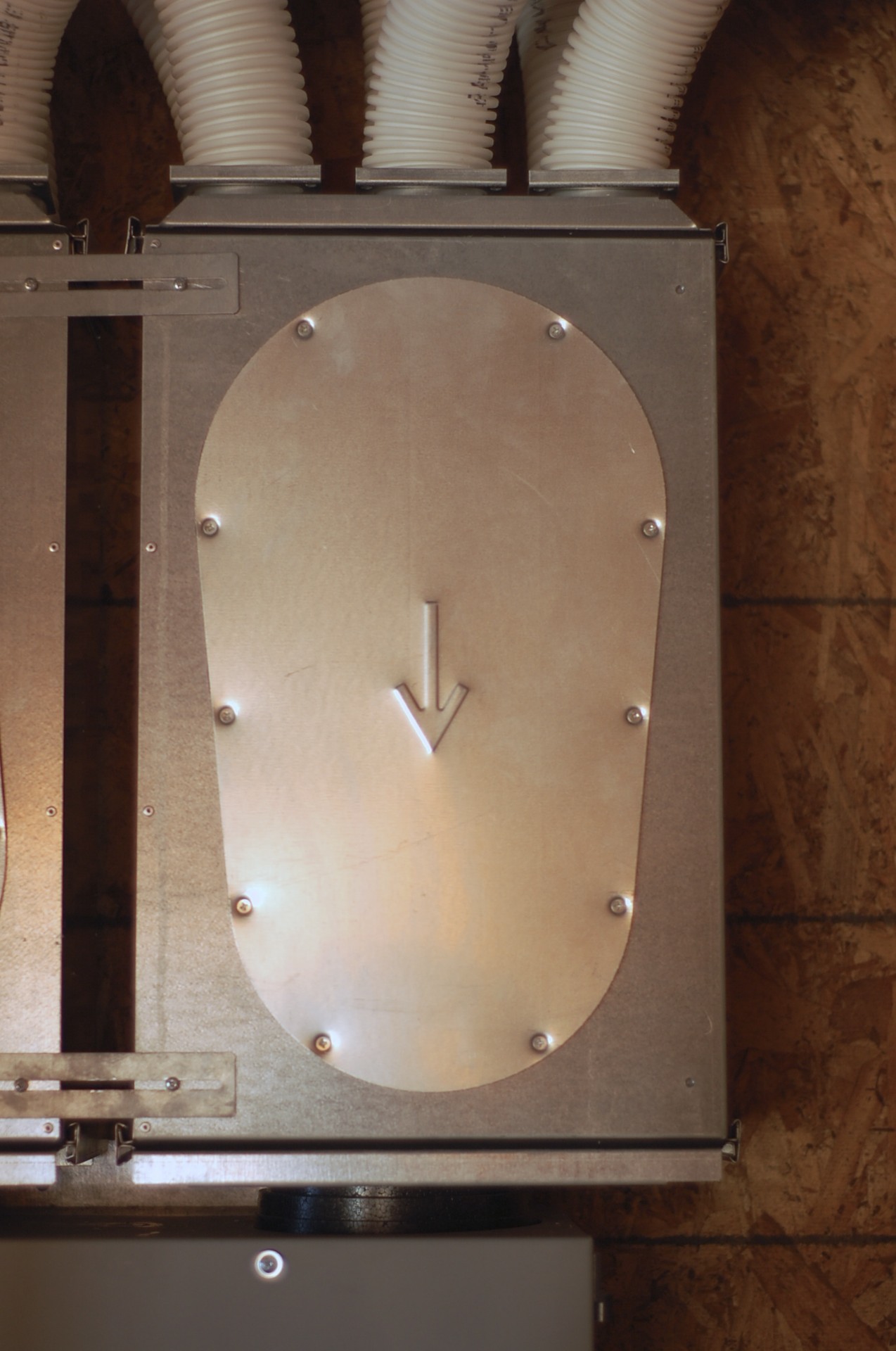

the tubing terminates in the ceiling of the mechanical room. 6 supply tubes and 6 exhaust tubes. manifolds gather the supply and exhaust tubes respectively and connect them to the unit.

exhaust air flows through the machine, the heat is captured in the core, and the air is expelled to the outside.

fresh air is brought into the machine from the exterior, and warmed by the heat captured from the outgoing air. the zehnder is about 92% efficient and uses just 7.1 watts / cfm.

the fresh air supply and exhaust are ducted in well insulated metal ductwork from the bottom of the unit to the exterior. the fresh air supply is located high on the exterior wall with the exhaust about 10' below. the duct penetrations were carefully air sealed to the plywood air-barrier. this unit also requires a condensate drain that we've tied with an air gap into the kitchen waste pipe.

the main controller will be located in the kitchen, providing the ability to boost the ventilation rate temporarily to 35 cfm while cooking. each bathroom will have a timed switch to boost the rate to 24 cfm if needed after a shower. we also conveniently have an operable window located in the kitchen and both showers.

thanks to IM Plumbing for help with the installation, and to Matt Grove from Zehnder for help with the design.

sheetrock has wrapped up and painting has begun. check back soon for more.